You don’t have to stand out to play a crucial role. Our seals operate invisibly – and yet they are indispensable key components of machines and industrial plants. Although they often go unseen, they are always appreciated thanks to their outstanding quality, maximum reliability, and innovative design.

EagleBurgmann international

EagleBurgmann WORLDWIDE

With around 250 locations and 90 serve centers, we are represented in the most important economic regions of the world. The advantages are clear: short paths to our customers, fast response times and a shared language.

Rely on Excellence

Our products keep sealed – period.

Rely on Excellence

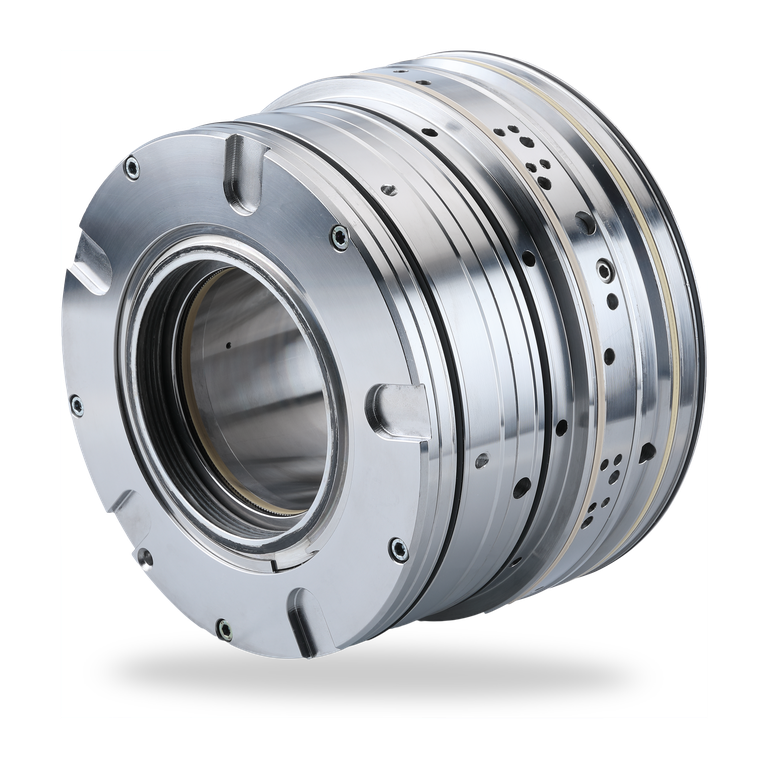

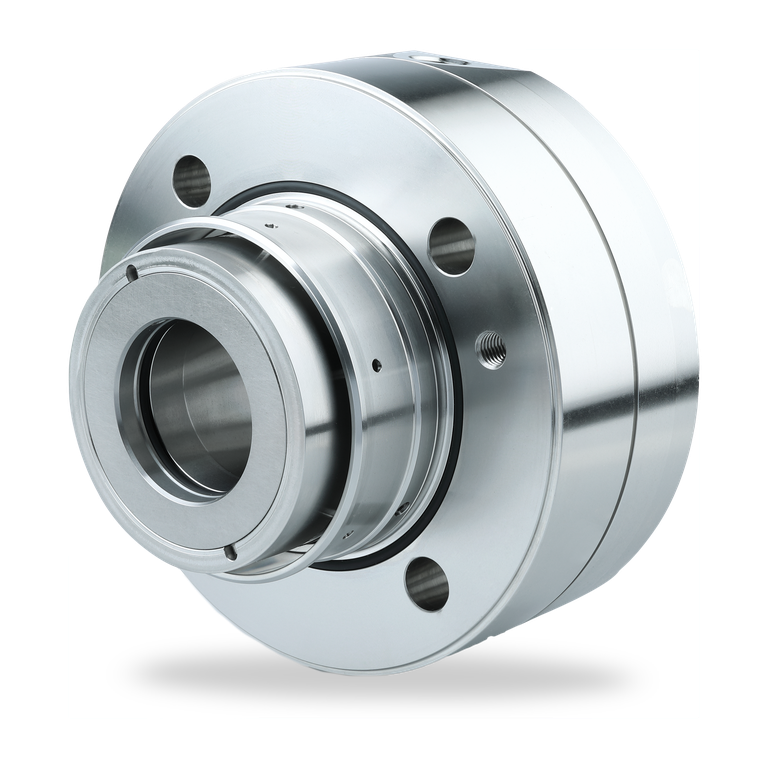

Discover our unique range of mechanical seals

From elastomer bellows seals, component seals and metal bellows seals to agitator, compressor and marine seals: Our range of mechanical seals delivers the right solutions wherever reliability and safety count.

Rely on Excellence

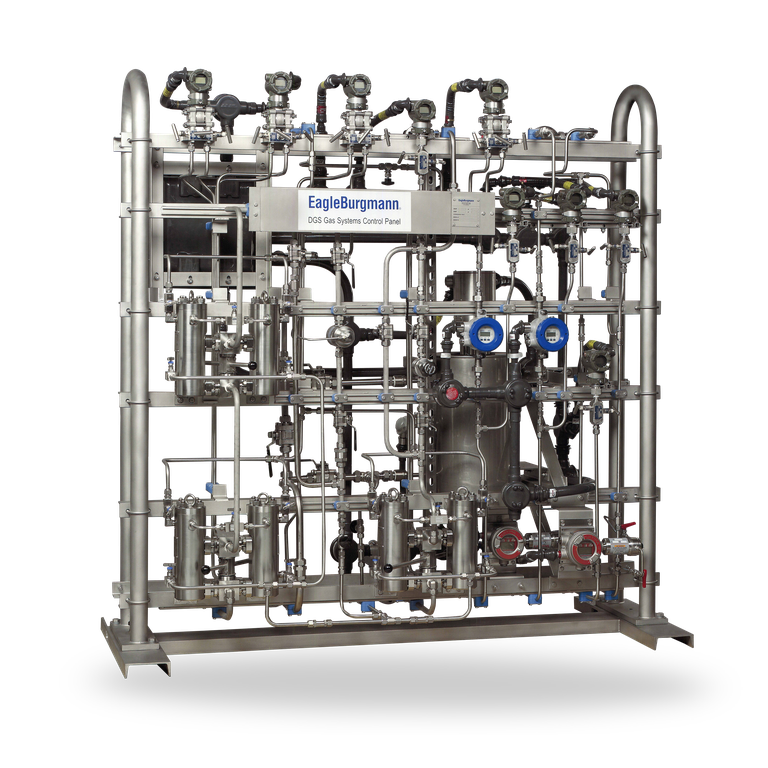

Seal supply systems for reliable operation

Depending on their use, design and mode of operation, mechanical seals and magnetic couplings need supply systems for flushing, cooling, pressure application and leak compensation. We deliver everything from a single source – from design to commissioning. We can also ensure supply system compliance with API 682.

Rely on Excellence

Magnetic couplings for the most demanding applications

EagleBurgmann offers the most consistent sealing technology for demanding applications that set very high requirements. Our hermetically sealed magnetic couplings guarantee leak-free and maintenance-free pumping and mixing. The media remain within closed system circuits – nothing gets in nothing gets out.

Rely on Excellence

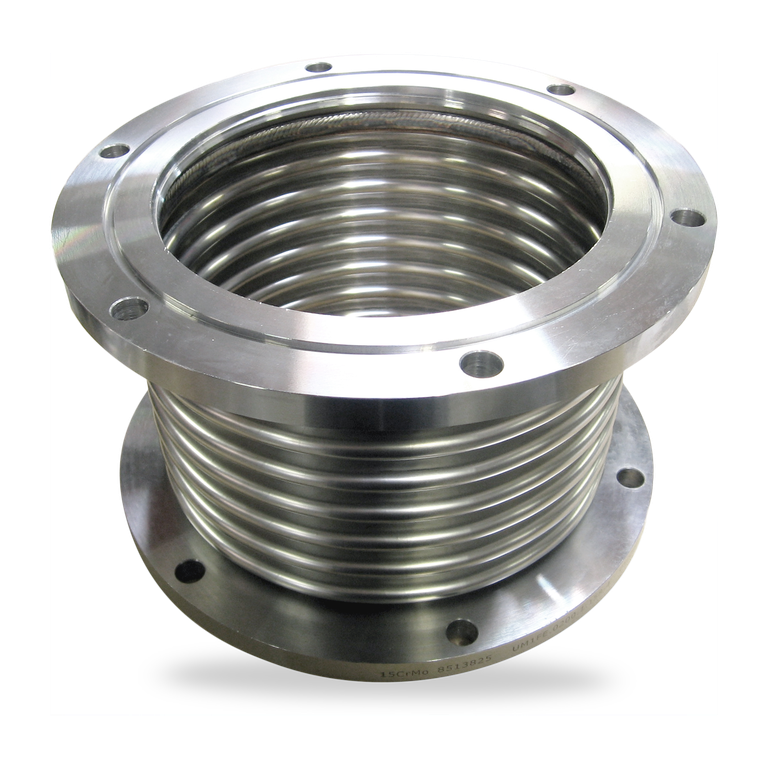

Expansion joints for every application

Expansion joints provide for flexible connecting elements in air and extraction shafts, as well as pipeline systems. However, they must compensate for pressure and temperature fluctuations, vibrations and offsets at the connection points. We supply optimal, reliably sealing and media-resistant solutions for every application.

- Info